MANAGER 3000+

Group regulation device for COMFORT applications MANAGER 3000+

Factory-engineered plant room control for chillers, heat pumps and units for simultaneous and independent production of chilled and hot water. Dedicated to both Comfort and Process applications, MANAGER 3000+ is the ideal solution to efficiently control and manage hydronic groups of chillers on a centralized plant room. Thanks to unique control algorithms, MANAGER3000+ selects the best sequence of unit operation, smartly manages heat loads according to the plant demand and gives users a high-end monitoring tool to check the plant conditions. This ensures stable and reliable control under any condition, complying with the most restrictive standards of ‘uptime’ required in comfort and process cooling applications.

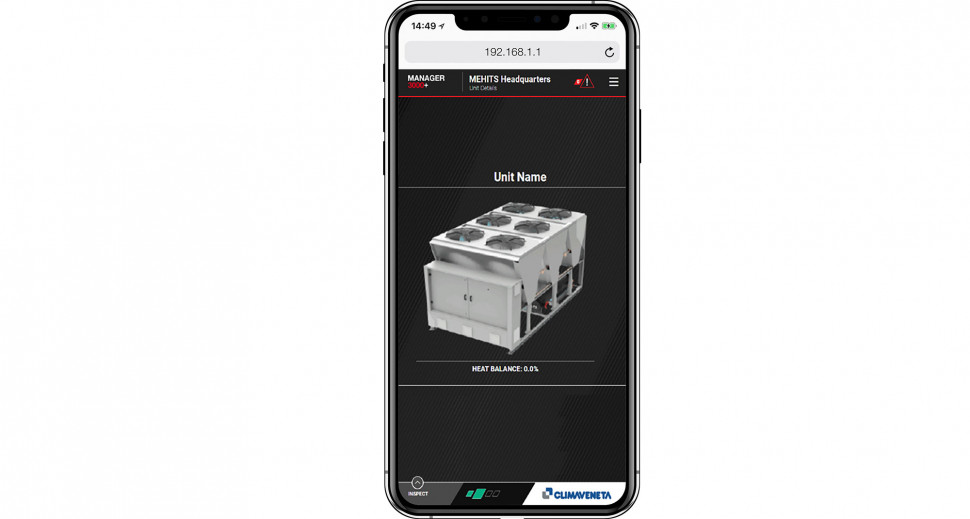

Responsive user interface.

MANAGER3000+ features a new responsive interface which is easy-to-use from any web browser and compatible with all smart devices (smartphones and tablets).

Smart Control Logics

MANAGER3000+ performs advanced control logics for managing the heat loads in the most efficient and cost-saving way.

Load BALANCING control logics

The cooling and heating plant demand is equally divided among the available units, fully exploiting the ability of increasing the efficiency during partial load operations.

Load SATURATION control logics

The total cooling and heating demand system is supplied by the system by running each individual unit up to its maximum power before activating and additional unit in the sequence.

OPTIMIZED free cooling operation

The free cooling mode exploits the maximum free cooling surface available among all the units.

When the cooling demand exceeds the available free cooling energy, MANAGER3000+ activates the compressors in order to meet the full plant cooling demand. Standard mechanical chillers maintain a lowest priority and are added in the control sequence after the free cooling units operating in full load.

Quick and easy access from your mobile

Mobile and smart devices can access the MANAGER3000+ via Wi-Fi or via LAN connection.

No need to stand in front of the unit’s electrical switchboard since all parameters are available via smartphone.

Ideal to manage complex HVAC systems

Suitable to manage up to 8 air-source and water-source units MANAGER3000+ selects the best sequencing for unit operation, smartly manages heat loads according to the plant demand and gives users a valid monitoring tool to check the plant conditions. This ensures stable and reliable control in any condition, complying with the strictest standards of ‘uptime’ required in comfort and process cooling applications.

Precious support to the service activities

For the client’s complete peace-of-mind, MANAGER3000+ offers devoted services aimed at making the service activity easier and quicker. It also includes an email service for quick notification to Site Managers, Site Service & Maintenance, Facility Managers.

Features

• Wall mounting electrical panel with glass double door (h806 x w606 x d250)

• 10.1” Touch-screen display

• IP66 international protection

• IK08 mechanical protection

• Variable primary flow piping configuration

• Optimized free-cooling plant operation

• Native web-based interface

• Keyboard function via direct Wi-Fi connection

• Mail service for alarms notification

Plant Configuration

Suitable to manage up to 8 air-source and water-source units

• 2-PIPE SYTEMS, standard chillers for the production of chilled water on the same water circuit

• 2-PIPE SYTEMS, free-cooling chillers for the production of chilled water on the same water circuit

• 2-PIPE SYTEMS, reversible heat pumps for the production of chilled and hot water on the same water circuit with seasonal change-over

• 4-PIPE SYTEMS, Integra units for simultaneous and independent production of chilled and hot water on two independent water circuits

• 4-PIPE SYTEMS, mixed installation of Integra units and chillers for simultaneous and independent production of chilled and hot water on two independent water circuits

Alarm Notification

MANAGER3000+ offers an email service for quick notification of system failures. The notification is available to all users as Site Managers, Site Service & Maintenance, Facility Managers and includes all the most relevant information related to:

• Site name

• Alarm type and code

• Status and description

• Date/Time of the event

Control Logics

• Load BALANCING control logics

The cooling and heating plant demand is equally divided among the available units, fully exploiting the ability of increasing the efficiency during partial load operations.

• Load SATURATION control logics

The total cooling and heating demand system is supplied by the system by running each individual unit up to its maximum power before activating and additional unit in the sequence.

• OPTIMIZED free cooling operation

The free cooling mode is operated in order to exploit the maximum free cooling surface available among all the units. When the cooling demand exceeds the available free cooling energy, MANAGER3000+ activates the compressors in order to meet the full plant cooling demand. Standard mechanical chillers maintain a lowest priority and are added in the control sequence after the free cooling units operating in full load.

System accessibility

Mobile and smart devices can access the MANAGER3000+ via Wi-Fi or via LAN connection. No need to stand in front of the unit’s electrical switchboard since all parameters are available via smartphone. Easy accessibility is possible also in case of any restriction:

• It improves and accelerates maintenance and service activities from centralized office to people operating on-site

• It reduces travel costs in case of trouble shooting and operator assistance

• Plant room spread out between different floor levels or buildings

• Protected areas or with restricted accessibility

• Uncomfortable weather conditions

Responsive user interface - GENERAL OVERVIEW

• SYSTEM DASHBOARD

The most relevant operating variables of the plant are displayed, in addition to pre-configured charts with the behavior of the common temperatures of both chilled water and hot water primary circuits.

• ALARM WIDGET

The user is informed about high-priority and low-priority alarms, signaling relevant information for both plant and unit operation.

• INSPECTION BAR

Always available in the footer of the each page, it shows the number of active units in the actual control sequence and their status (green = active, red = in alarm).

Responsive user interface - UNIT DETAIL

• BANNER ALARMS

It gives a direct and instantaneous indication on high-priority alarms.

• UNIT DETAIL

This provides a comprehensive overview of the most relevant operating variables of each individual unit without necessarily being physically nearby. A dedicated group of widgets shows all circuits and relevant compressors running statuses as well as the electrical power consumption acquired from the electronic controller installed on-board (when the function is available).

VPF - Variable Primary Flow

MANAGER3000+ controls the circulation of fluids through the system according to the actual cooling and heating plant demand. In the event of a low system load, the minimum water flow across the units’ exchanger is managed by the modulating valve that diverts part of the water flow rates through the by-pass circuit. The speed's control of primary pumps is based on ΔP (pressure).

• MAJOR BENEFITS

• Reduction of investment costs by eliminating circulation pumps in secondary circuits

• Reduction of pumps’ electrical energy consumption deriving from modulating the water flow rate.

VPF.D - Variable Primar Flow with Decoupler

This configuration foresees the presence of variable pumps in both the primary and secondary circuits. Minimum circulation is ensured thanks to the presence of a decoupling line between the primary and secondary circuits. The speed's control of primary pumps is based on ΔT (temperature). The water flow varies according to:

• the actual energy demand of secondary circuits

• the ΔT of the units in the primary circuits

• MAJOR BENEFITS

• Reduction of energy consumption deriving from the variable speed pumps on both primary and secondary circuits

• System reliability thanks to the coexistence and independence of primary and secondary water circuits.

<<<<<< Thông tin tham khảo >>>>>>>